Logistics Automation Solution

SPING SERIES

Maximizing Sorting Efficiency in Limited Space

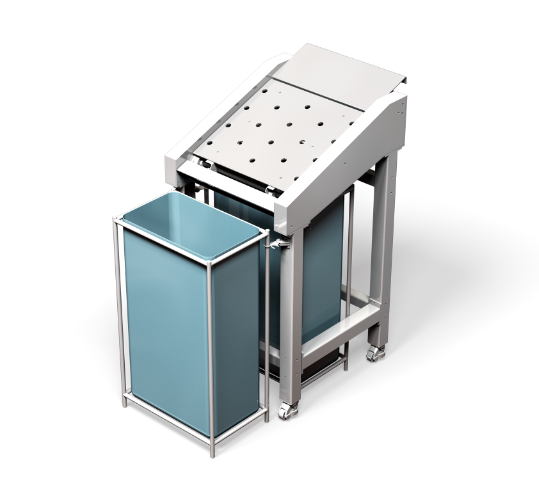

FLAP SORTER(Secondary Divider)

In high-volume logistics, optimizing space while maintaining sorting efficiency is a critical challenge. Spring Series is designed to address this by enabling the installation of a large number of sorting chutes in a compact area. This innovative solution leverages a two-stage sorting process: an initial sorting with wheel sorters, followed by a secondary sorting with flap sorters. By reducing the number of wheel sorters needed by half, Spring Series minimizes the installation footprint while maximizing performance. Discover how Spring Series can revolutionize your sorting operations with efficiency, precision, and space optimization.

Key Benefits

Cost-effective

Space-Efficient Design

Low Maintenance

&Long Lifespan

| Model | Sping 01 | Sping 02 | Sping 03 | |

|---|---|---|---|---|

|  |  | ||

| Parcel dimensions (W x L x H) | Max. (mm / Kg) | 300 x 300 x 150 / 4 | 400 x 400 x 200 / 5 | 300 x 300 x 150 / 4 |

| Min. (mm / g) | 100 x 100 x 1 / 100 | 100 x 100 x 1 / 100 | 100 x 100 x 1 / 100 | |

| Sorting direction | 2-way | 2-WAY | 2-WAY | |

| Processing performance | Max. 5,000 items / h | Max. 5,000 items / h | Max. 6,000 items / h | |

| Coating | Low-friction powder coating | Low-friction powder coating | Low-friction powder coating | |

| Operating temperature | -20℃ ~ 45℃ | -20℃ ~ 45℃ | -20℃ ~ 45℃ | |